Just In Time Printing Solutions for packaging

Analog, digital or hybrid printing on any roll material or direct printing on products and materials.

For Every Pack, Form, Material and Process. Boundless Opportunities…

No matter the run or batch size and no matter the substrate you use, Hapa technologies help make your packaging production more cost effective, flexible and environmentally Friendly.

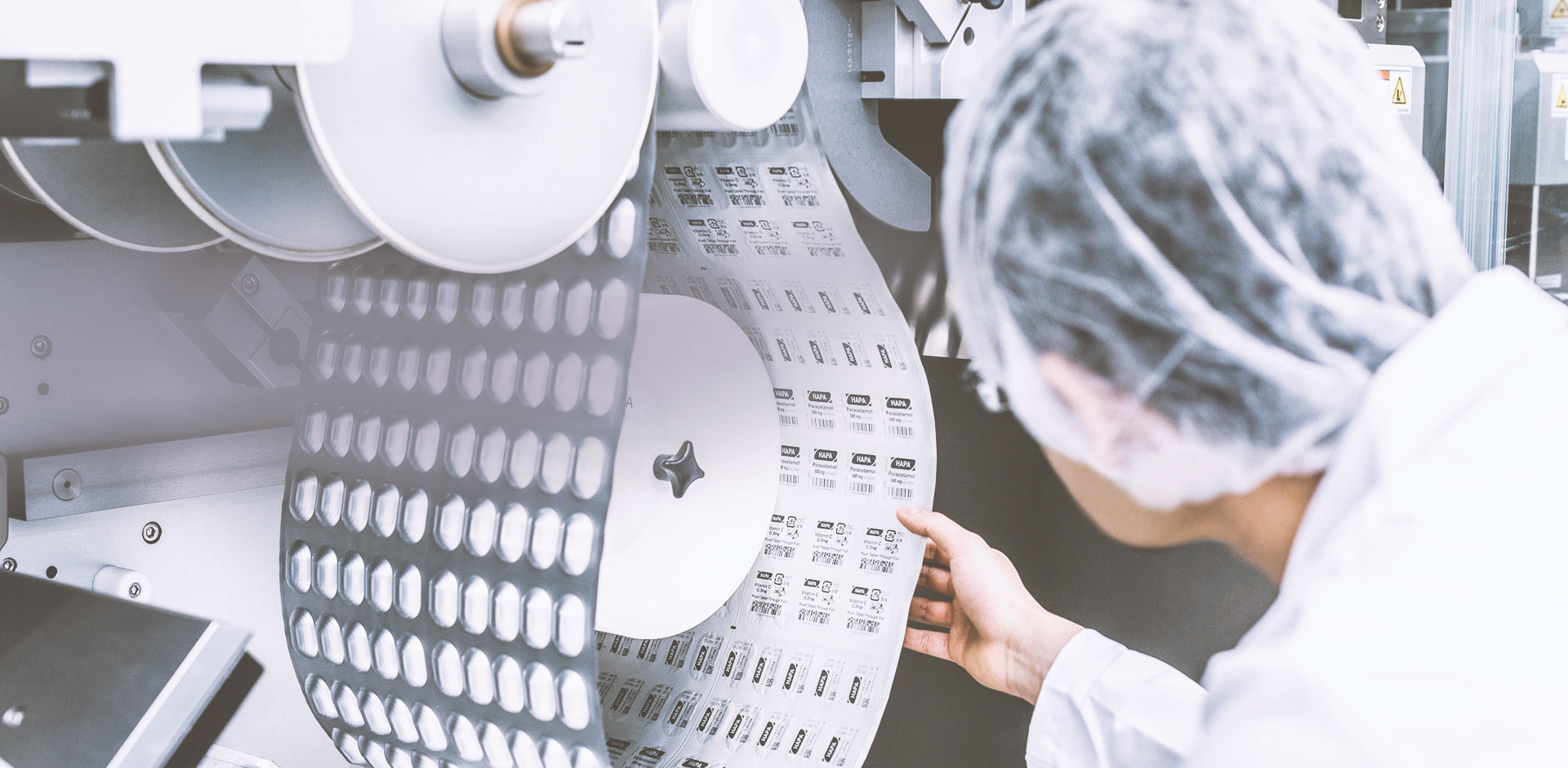

Web and Direct printing on packaging or components – from blister lidding foils, blisters, labels and cartons to blow fill seal and IV bags – rely on a partnership: your vision and creativity with our passion and expertise, your passion and expertise with our vision and creativity.

Inline and near to line late stage customisation solutions for:

- Foils

- Web materials

- Lidding materials

- Bottles

- Caps

- Labels

- Cartons

- Blister Foil & Packs

- Tyvek & medical paper

- Direct Object Printing

- Blow Fill Seal (BFS)

- FMCG

- Components

- IV Bags

- Medical devices

- Consumer Goods

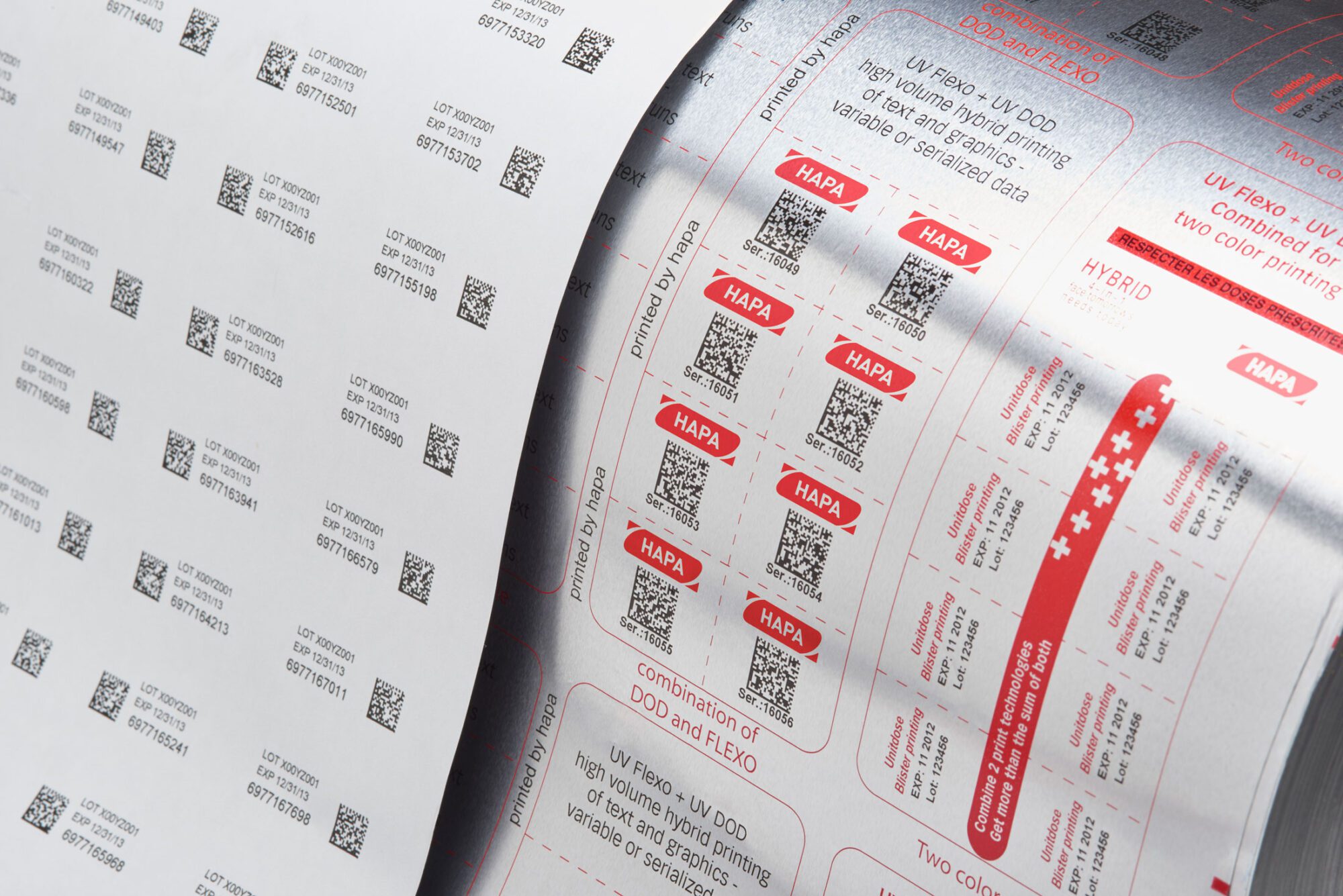

Digital Printing

- Flexo Printing

- Hybrid Printing

- Laser Engraving

Request a

Callback

Contact our team to discuss your needs ...